Honda’s engine development philosophy has consistently prioritized high-revving performance, exceptional reliability, and innovative engineering solutions. From their origins in motorcycle manufacturing to becoming one of the world’s most respected automotive engine producers, Honda has maintained a unique approach to internal combustion engine design that emphasizes efficiency and performance.

Honda’s Engineering Philosophy

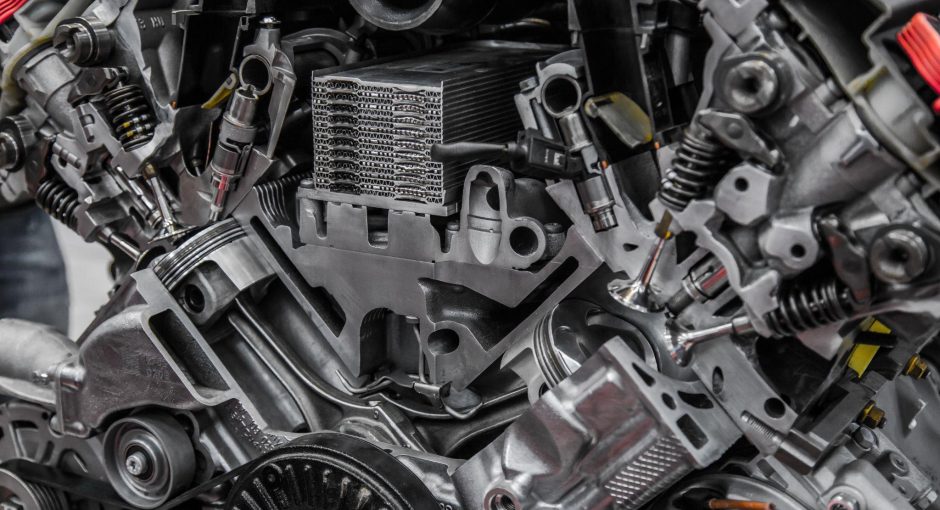

Honda’s approach to engine development stems from their motorcycle heritage, where power-to-weight ratios and high-rpm performance were crucial. This background influenced their automotive engine designs, creating powerplants that typically featured higher compression ratios, more aggressive cam profiles, and superior breathing characteristics compared to competitors.

The company’s founder, Soichiro Honda, believed in extracting maximum performance from each cubic centimeter of displacement. This philosophy led to engines that often produced more power per liter than competing designs while maintaining exceptional reliability and longevity.

Honda’s commitment to precision manufacturing established early quality standards that became industry benchmarks. Tight tolerances, premium materials, and innovative construction techniques created engines that performed consistently over extended service lives while requiring minimal maintenance.

VTEC Technology Revolution

The introduction of VTEC (Variable Valve Timing and Lift Electronic Control) technology in the late 1980s revolutionized Honda’s engine performance capabilities. This system allowed engines to operate with conservative cam profiles at low RPM for fuel economy and emissions compliance, then switch to aggressive profiles for maximum power at higher RPM.

VTEC implementation required sophisticated engineering solutions to ensure reliable operation under varying conditions. The system’s mechanical simplicity belied its effectiveness, using oil pressure to engage different cam profiles seamlessly during operation. This approach provided performance benefits without compromising reliability.

The psychological impact of VTEC engagement, often accompanied by a distinctive sound change, became part of Honda’s performance identity. Enthusiasts appreciated the tangible transition point where engines transformed from economical commuter powerplants to high-performance machines.

High-Performance Applications

Honda’s naturally aspirated engines achieved remarkable specific output figures through advanced breathing and combustion chamber designs. The legendary B-series engines, particularly the B18C found in the Integra Type R, demonstrated Honda’s ability to extract extraordinary power from relatively small displacements.

The K-series engines represented Honda’s evolution into larger displacement performance applications while maintaining their high-revving characteristics. These engines incorporated lessons learned from decades of B-series development while adding modern technologies like drive-by-wire throttle control and advanced engine management systems.

Honda’s approach to forced induction has been more conservative than some manufacturers, but their turbocharged applications have demonstrated exceptional reliability and linear power delivery. The recent trend toward turbocharged Honda engines maintains the brand’s commitment to responsive performance while improving fuel economy.

Manufacturing Excellence

Honda’s engine manufacturing processes have consistently set industry standards for precision and quality control. Advanced machining techniques, strict material specifications, and comprehensive testing procedures ensure that each engine meets Honda’s exacting standards before leaving the factory.

The company’s investment in automated manufacturing systems has enabled consistent production quality while maintaining the precision required for high-performance applications. These systems reduce variation between individual engines while ensuring that performance specifications are met consistently.

Quality control measures in Honda engine production include extensive testing protocols that verify performance, emissions compliance, and durability characteristics. These procedures help maintain Honda’s reputation for producing engines that perform reliably throughout their service lives.

Fuel Efficiency Innovations

Honda’s commitment to fuel efficiency has driven numerous innovations in engine technology, including lean-burn combustion systems, advanced ignition timing controls, and sophisticated fuel injection systems. These technologies optimize combustion efficiency while maintaining performance characteristics.

The development of Honda’s i-VTEC system added variable cam timing to the original VTEC concept, allowing more precise control over valve events throughout the engine’s operating range. This refinement improved both performance and fuel economy while reducing emissions output.

Honda’s work with alternative fuels, including natural gas and hydrogen, has required significant engine modifications while maintaining reliability and performance standards. These alternative fuel applications demonstrate Honda’s engineering flexibility and commitment to environmental responsibility.

Hybrid Powertrains

Honda’s approach to hybrid technology has emphasized simplicity and reliability, with systems that complement rather than complicate the driving experience. The Integrated Motor Assist (IMA) system provides electric assistance to internal combustion engines while maintaining familiar driving characteristics.

The two-motor hybrid system used in vehicles like the Accord Hybrid represents Honda’s evolution toward more sophisticated hybrid powertrains. This system allows for electric-only operation at low speeds while seamlessly integrating internal combustion power for acceleration and highway driving.

Honda’s hybrid engine modifications include Atkinson cycle operation, specialized lubrication systems, and optimized combustion chamber designs that maximize efficiency while maintaining reliability. These adaptations demonstrate Honda’s ability to modify proven engine designs for hybrid applications.

Aftermarket and Tuning Culture

Honda engines have become favorites among tuning enthusiasts due to their robust construction and response to modifications. The availability of performance parts and the engines’ tolerance for power increases have created vibrant aftermarket communities worldwide.

The popularity of Honda engine swaps has led to extensive development of conversion kits and supporting components. Enthusiasts often seekJDM Honda engine for sale options that were never available in their domestic markets, accessing higher-performance variants with different specifications.

Turbocharger and supercharger applications for Honda engines have been extensively developed by aftermarket companies. The engines’ strong internal construction and sophisticated engine management systems generally handle forced induction applications well when properly implemented.

Motorsport Heritage

Honda’s involvement in Formula One racing has driven numerous engine technology developments that eventually found their way into production vehicles. The company’s F1 engines have demonstrated exceptional power density and advanced materials technology under the most demanding conditions.

Touring car racing applications have proven Honda engines’ durability and performance potential in extended competition use. These motorsport applications often serve as proving grounds for technologies that later appear in production engines.

The success of Honda engines in various racing series has enhanced their reputation among performance enthusiasts and contributed to strong aftermarket support. Racing success translates directly into consumer confidence and aftermarket development investment.

Modern Developments

Current Honda engine development focuses on maximizing efficiency while maintaining performance characteristics through technologies like direct injection, turbocharging, and advanced engine management systems. These developments promise to maintain Honda’s reputation for responsive, efficient powerplants.

The integration of electrification technologies with traditional internal combustion engines represents Honda’s approach to future powertrain development. These hybrid systems leverage Honda’s engine expertise while addressing environmental concerns and efficiency requirements.

Honda’s continued investment in internal combustion engine development suggests long-term commitment to optimizing these powerplants even as the industry moves toward increased electrification. This approach ensures that Honda engines will remain competitive and desirable for years to come.